Condoms help protect you from sexually transmitted infections, including AIDS, as well as unintended pregnancies.

Sagami condoms are made from either natural rubber latex or polyurethane.

Here, we’ll introduce how our natural rubber latex condoms are made.

The natural rubber latex used to make condoms is primarily harvested from rubber plantations in Southeast Asia.

As shown in the photo, diagonal cuts are made in the bark of rubber trees to collect the sap as it flows out.

The harvested latex is carefully refined and concentrated, and only “premium-grade” latex that passes rigorous testing across a wide range of criteria is exported to us.

Of course, we also conducts strict quality inspections in-house, and only latex that passes these tests is accepted as a raw material.

To give condoms strength and elasticity, and to ensure uniformity of the raw material, several types of chemical are blended.

Because this blending process plays a crucial role in determining the fundamental quality of the condom, it is carried out with great care.

The liquid natural rubber latex, blended in the previous step, is poured into a large tank.

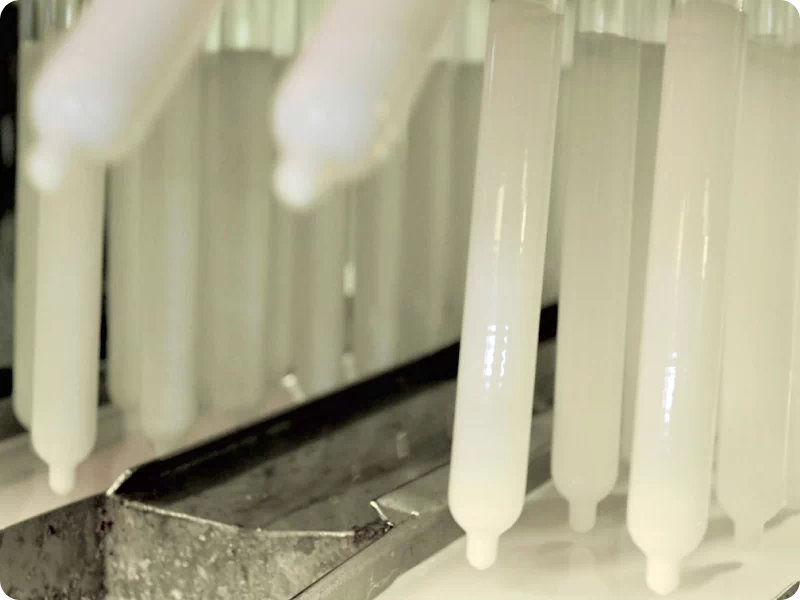

Glass molds shaped like condoms are dipped into the latex.

When the molds are lifted, it clings to them and then is dried, Finally, once removed from the mold, it takes the shape of a condom.

To check for microscopic holes called “pinholes,” every single condom undergoes a 100% inspection.

Each condom is placed over a mold shaped like a condom, then submerged in a warm water bath while an electric current is applied.

If even the smallest hole is present, the current passes through the mold, and the condom is automatically identified as defective and removed by the system.

Only the condoms that pass this test are rolled up into the familiar form you see.

Each rolled condom is coated with lubricant and packaged individually.

For scented condoms, the flavor is added at this stage.

After the individually packaged condoms are packed into consumer boxes, the lot number and expiration date are printed.

Each box then undergoes a weight check to ensure there are no missing or excess items before being finalized as a finished product.

Various Tests

This is one of the tests used to measure the strength of a condom.

Air is continuously pumped into the condom until it bursts, measuring both the volume of air it contains at the point of rupture and the burst pressure it withstands.

According to ISO 4074, the international standard for condoms, the condom must hold at least 18 liters of air and withstand a burst pressure of at least 1.0 kilopascal (for nominal widths between 50 mm and 56 mm).

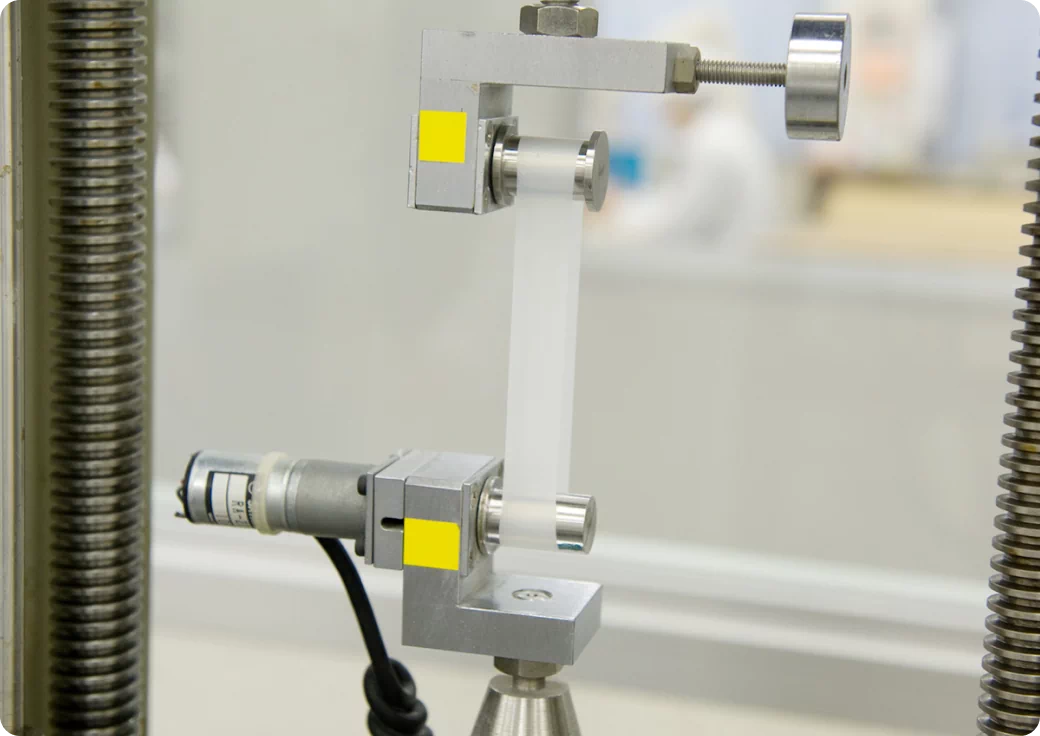

This is another test used to measure the strength of a condom.

A ring-shaped section of the condom is stretched from both ends until it breaks, measuring how much it stretches and how much force it can withstand before breaking.

This is a test to check for pinholes—microscopic holes—in the condom.

Water is poured into the condom and left for a set period of time to see if any leakage occurs. This visual inspection also confirms that the condom maintains a uniform shape.

After the hanging water-leakage test, the condom is removed, tied at the open end, and rolled by hand over an absorbent sheet while applying pressure.

If there is a pinhole, the water will leave a mark on the sheet, which enable to detect the holes that could not do by water leakage test.

Our condoms are manufactured in facilities certified under ISO 13485, the international quality management standard for medical devices.

Strict manufacturing and quality control procedures are followed at every stage—from raw material inspection and blending, to packaging and final inspection before shipping.

Only products that pass all tests are delivered to our customers.

We encourage everyone to use condoms properly—without embarrassment or hesitation.